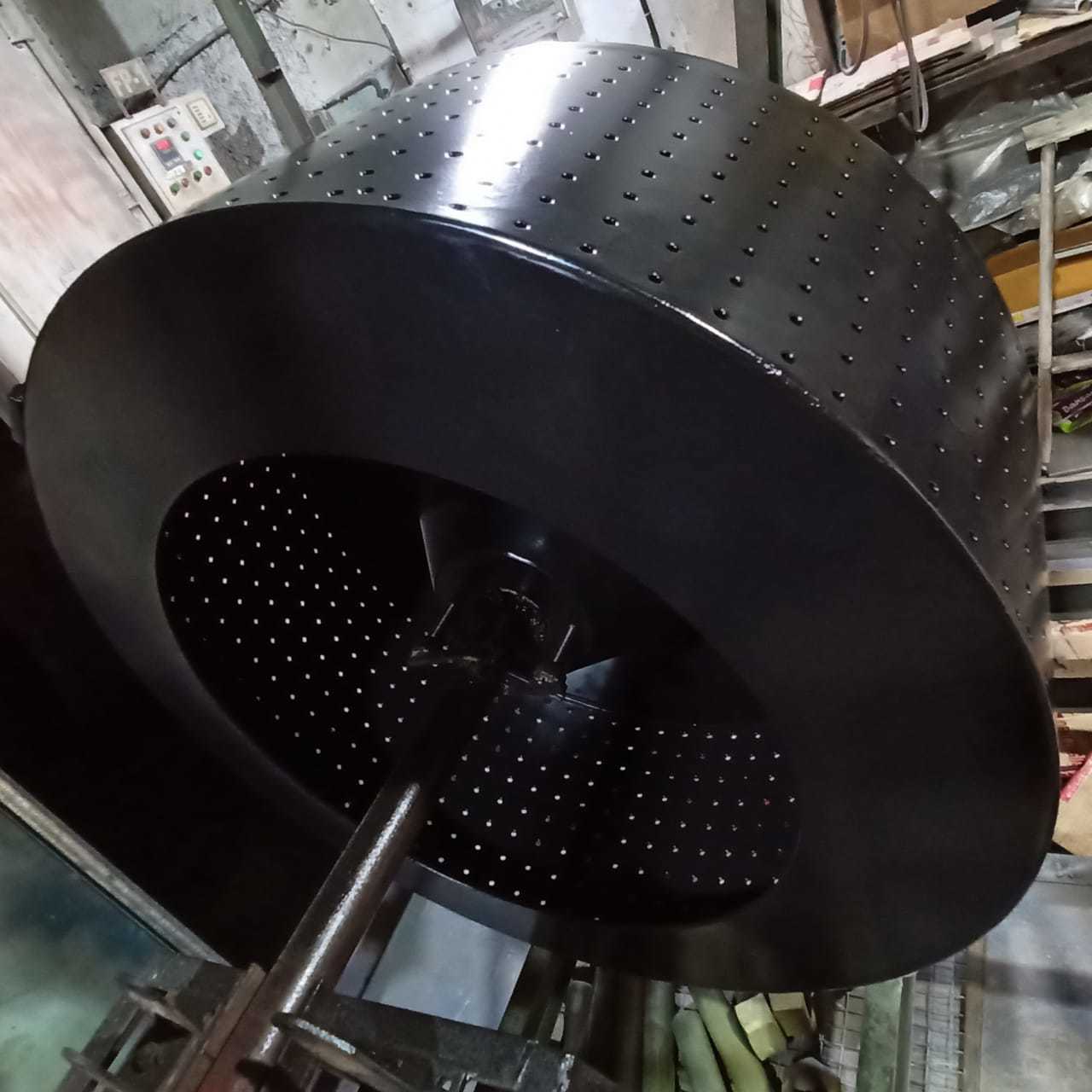

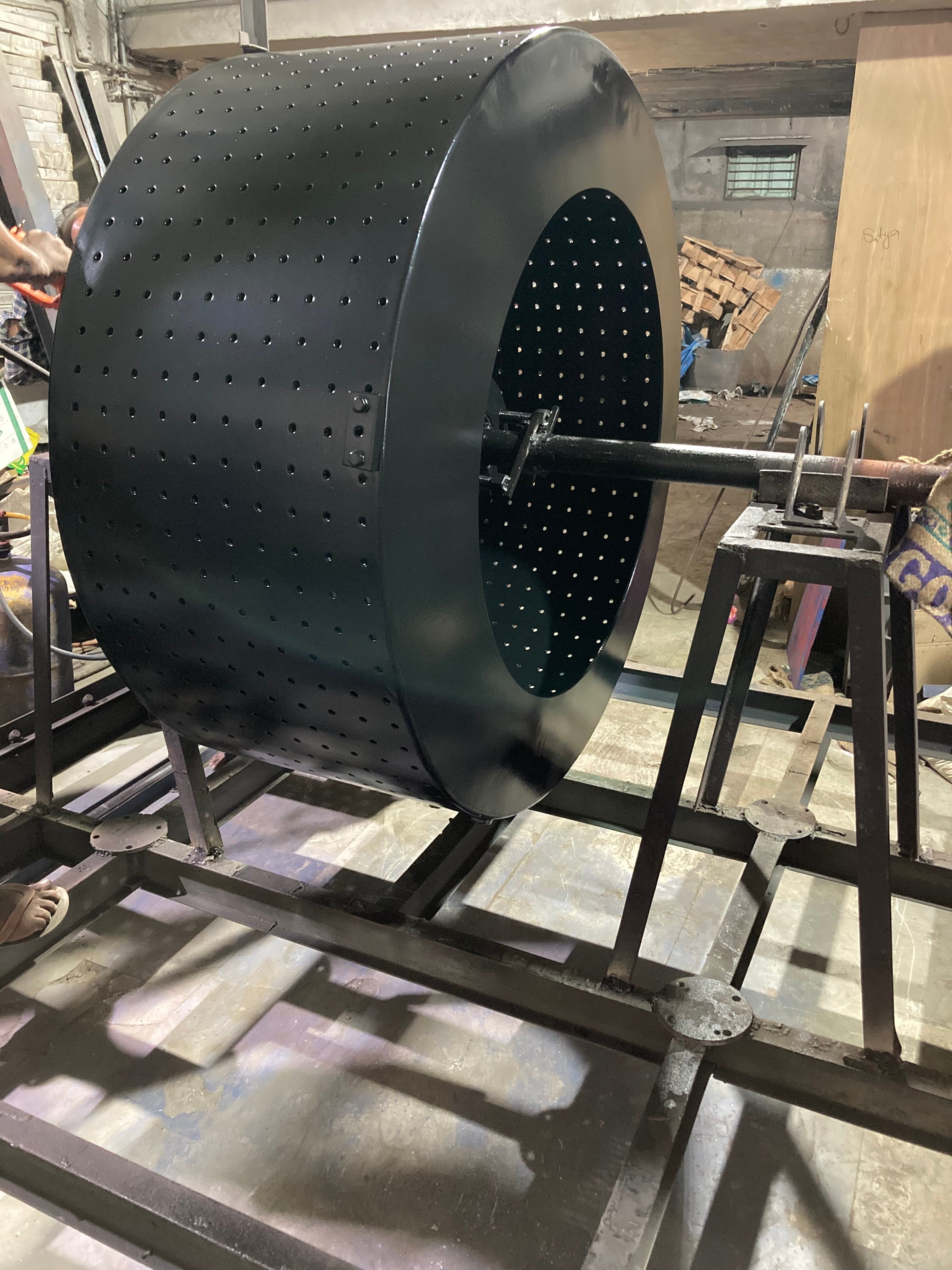

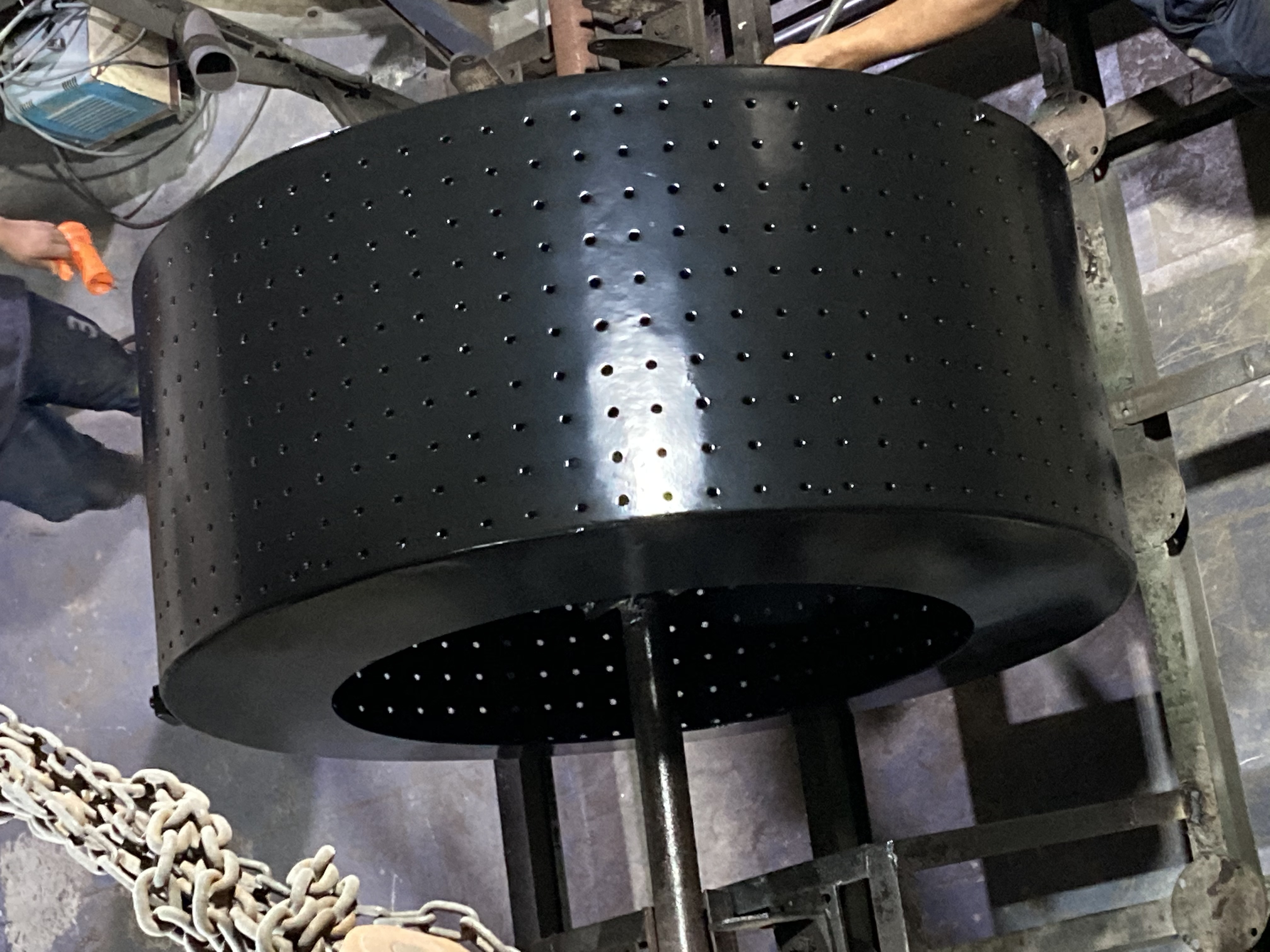

48 Centrifuge Basket Halar Anti Static Coating

Price 2200 INR/ Square Foot

48 Centrifuge Basket Halar Anti Static Coating Specification

- Base Material

- Stainless Steel

- Process Method

- Fluidized bed or electrostatic spray

- Coating Inspection

- Spark test, thickness gauge

- Melting Point

- 220°C

- Shelf Life

- Long-lasting performance

- Adhesion Strength

- High adhesion to metal substrates

- Weight

- Depends on basket size and coating thickness

- Abrasion Resistance

- Superior durability against wear

- Application

- Industrial filtration, Centrifuge baskets

- Chemical Resistance

- Excellent resistance to acids, alkalis, and solvents

- Corrosion Protection

- Outstanding corrosion resistance in harsh environments

- Capacity

- 48 Inch

- Coating Adhesion Test Standard

- ASTM

- Product Name

- 48 Centrifuge Basket Halar Anti Static Coating

- Coating Material

- Halar (ECTFE) Anti Static

- Maximum Operating Temperature

- 150°C

- Custom Sizes

- Available on request

- Electrical Properties

- Anti-static properties for safe operation

48 Centrifuge Basket Halar Anti Static Coating Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 100 Square Foots Per Week

- Delivery Time

- 7 Days

About 48 Centrifuge Basket Halar Anti Static Coating

Halar Anti Static Coating

With our excellent coating services, Polymech Engineering helps you to get superior protection and performance for your parts. We provide effective Halar Anti Static Coating based on your production requirements and operating environment. Also, we use latest application technology and finest inputs to create optimal coating works. We meet perfect finish and performance for your components and that too at an affordable price.

We provide Halar coatings for chemical process equipment for handling corrosive chemical as well as dissipating undesirable static charge. Undesirable static charges are generated during the handling and storing of solvents or during handling or generation of fine organic powders. There is a potential risk of vapor or air mixture or powder. If any accidental sparks due to the friction it will lead to fire and explosion. This coating is conductive throughout its layers and dissipates static charges in less than 0.1 seconds.

Halar XPH 832

Halar XPH 832 is a black, semi crystalline melt processable fluorinated resin that is used in full compliance with the federal food, drug and cosmetic act. It is designed for Electrostatic Powder Coatings and is particularly recommended for use as an antistatic coating in the protection and anti corrosion applications.

Main Features

- Black color coating

- Antistatic properties

- Compliance to food contact

- Good chemical resistance

- Good thermal properties

- Optimum permeation resistance

- Outstanding flame resistance

- Good surface finish

SPECIFICATION

|

Country of Origin |

Made in India |

|

Brand |

HALAR ANTI STATIC |

Superior Chemical and Corrosion Resistance

The Halar Anti Static Coating excels against acids, alkalis, and solvents, ensuring the centrifuge basket performs reliably in aggressive chemical environments. Its advanced formulation provides outstanding corrosion protection, significantly extending the service life of centrifuge baskets, especially in industrial filtration setups where harsh chemicals are frequently encountered.

Highly Durable and Safe Operation

Its excellent abrasion resistance and high adhesion to stainless steel substrates make this coating ideal for demanding industrial use. The anti-static properties reduce the risk of electrical hazards during operation, supporting safe and efficient processes. The coating undergoes strict inspection using spark tests, thickness gauges, and complies with ASTM standards for consistent performance.

Customizable Solutions for Industrial Needs

Available for 48 inch centrifuge baskets, the Halar Anti Static Coating can be tailored to specific size requirements. With application expertise using fluidized bed or electrostatic spray methods, our service covers complete coating solutions for industrial clients across India. This flexibility ensures each basket provides optimum filtration, protection, and longevity.

FAQs of 48 Centrifuge Basket Halar Anti Static Coating:

Q: How is the Halar Anti Static Coating applied to the 48 centrifuge basket?

A: The coating is applied using either a fluidized bed or electrostatic spray process, which ensures uniform coverage and strong adhesion to the stainless steel basket surface.Q: What benefits does the anti-static property provide during operation?

A: The anti-static property reduces the risk of static electricity build-up, promoting safe operation in environments where flammable or volatile materials may be present.Q: When should the coatings performance be inspected?

A: Periodic inspections are recommended, employing spark tests and thickness gauges to ensure the coating remains effective and within ASTM standards throughout its service life.Q: Where can this coated basket be used?

A: The Halar coated centrifuge basket is suitable for industrial filtration systems, particularly where resistance to chemicals and abrasion is vital, and is available for installation across India.Q: What is involved in the testing process for the coatings adhesion and durability?

A: Coating adhesion and durability are verified through ASTM standard testing methods, including spark tests for integrity and thickness measurements for consistent protection.Q: Can the 48 centrifuge basket coating be customized for different applications?

A: Yes, custom sizes and specifications are available upon request, allowing adaptation to specific industrial needs and centrifuge models.Q: What is the shelf life of the Halar Anti Static Coating?

A: The coating is engineered for long-lasting performance, maintaining its protective and anti-static properties over extended use in challenging environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Halar Coating Category

Halar Coated 60 Inch Centrifuge Basket Coating Services

Price 2200 INR / Square Foot

Minimum Order Quantity : 100 Square Inches

Fluoropolymer Coating Services

Price 20 INR / Square Inch

Minimum Order Quantity : 1000 Square Inches

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free