à¤à¤¼à¤¾à¤à¤²à¤¨ 1424 à¤à¥à¤à¤¿à¤à¤

Price 3 आईएनआर/ Square Inch

MOQ : 250 Square Inches

à¤à¤¼à¤¾à¤à¤²à¤¨ 1424 à¤à¥à¤à¤¿à¤à¤ Specification

- Corrosion Resistance

- High

- Hardness

- 65-75 Shore D

- Solvent Resistance

- Good

- Features

- Excellent chemical resistance, low friction

- Storage Conditions

- Store below 25°C, dry place

- Adhesion

- Excellent to metal substrates

- Type

- PTFE Based Coating

- Color

- Blue

- Product Name

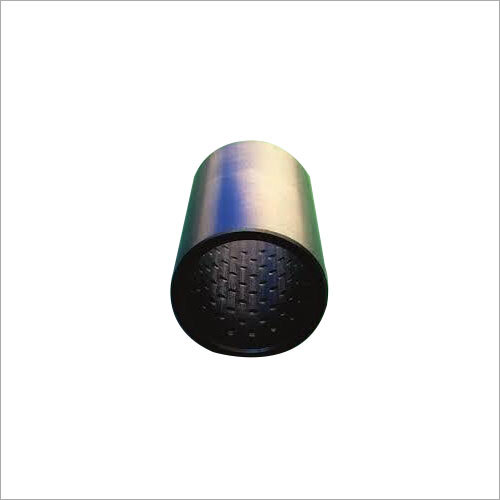

- Xylan 1424 Coating

- Shelf Life

- 12 months in sealed container

- VOC Content

- Low

- Usage/Application

- Industrial Coating

- Coating Thickness

- 20–30 microns

- Application Methods

- Spray, dip, brush

- Curing Method

- Heat Curable

- Temperature Range

- -195°C to +260°C

- Finish

- Smooth, semi-gloss

- Packaging Size

- 1L, 5L, 20L

à¤à¤¼à¤¾à¤à¤²à¤¨ 1424 à¤à¥à¤à¤¿à¤à¤ Trade Information

- Minimum Order Quantity

- 250 Square Inches

- आपूर्ति की क्षमता

- 2500 प्रति महीने

- डिलीवरी का समय

- 1 हफ़्ता

About à¤à¤¼à¤¾à¤à¤²à¤¨ 1424 à¤à¥à¤à¤¿à¤à¤

| Xylan Coating Type | Xylan 1424 |

| Xylan Coating Series | Xylan 1424 |

| Relative Density | 1.06 g/cm3 |

| Operating Temperature | -20 to 180 deg C |

| Dry Film Thickness | 25 to 30 microns |

We are offeringXylan 1424 Coating.

Other Details:

- It is an aqueous based, dry lubricant coating material primarily formulated to prevent corrosion and facilitate make up torque.

Superior Resistance and Versatile Application

Xylan 1424 offers high corrosion and chemical resistance, extending the life of metal components in tough industrial settings. Its smooth, semi-gloss blue finish, coupled with low friction properties, ensures reliable performance for applications ranging from heavy machinery to precision instruments. The coating adheres excellently to metals and can be applied via spray, dip, or brush methods, providing flexibility and efficiency for service providers across India.

Environmentally Friendly and Durable

With a low VOC formulation, Xylan 1424 is environmentally conscious while ensuring robust protection. The coating withstands a wide temperature range and maintains durability under harsh conditions, making it suitable for industries such as chemical processing, automotive, and manufacturing. Its heat-curable process guarantees a tough, long-lasting finish, even in the most demanding environments.

FAQs of Xylan 1424 Coating:

Q: How is Xylan 1424 Coating applied for optimal performance?

A: Xylan 1424 can be applied using spray, dip, or brush methods onto thoroughly cleaned metal surfaces. For best results, follow proper surface preparation and ensure even coating coverage before heat curing as specified in the product guidelines.Q: What are the main benefits of using Xylan 1424 Coating in industrial settings?

A: This coating provides excellent corrosion and chemical resistance, superior adhesion to metal substrates, a wide operational temperature range, and low friction, resulting in longer component life and reduced maintenance needs.Q: When should Xylan 1424 Coating be heat cured, and why is this necessary?

A: Heat curing should be performed after application, as recommended in the technical data sheet. This step is essential to achieve the ideal hardness, adhesion, and performance characteristics of the coating.Q: Where can Xylan 1424 Coating be effectively used?

A: It is best suited for industrial environments requiring robust protection, such as chemical plants, automotive components, manufacturing machinery, and any metal surface exposed to aggressive conditions.Q: What is the recommended storage condition for Xylan 1424 Coating?

A: Store Xylan 1424 in a tightly sealed container below 25C in a dry place to maintain its shelf life and product integrity for up to 12 months.Q: How does Xylan 1424 benefit service providers in India?

A: Service providers benefit from its easy application methods, reliable performance, and compliance with environmental standards due to its low VOC content. Availability in multiple packaging sizes also ensures operational flexibility.Q: What is the typical coating thickness and finish of Xylan 1424?

A: When properly applied, the coating achieves a thickness of 2030 microns, providing a smooth, semi-gloss blue finish that is both durable and aesthetically pleasing.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in XYLAN कोटिंग Category

XYLAN PTFE ड्राई लुब्रिकेंट कोटिंग सर्विस

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : स्क्वायर इंच/स्क्वायर इंच

मूल्य की इकाई : स्क्वायर इंच/स्क्वायर इंच

न्यूनतम आदेश मात्रा : 1

थर्मोवेल PTFE कोटिंग सेवा

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : स्क्वायर इंच/स्क्वायर इंच

मूल्य की इकाई : स्क्वायर इंच/स्क्वायर इंच

न्यूनतम आदेश मात्रा : 1

ज़ाइलन 8840 कोटिंग

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : स्क्वायर इंच/स्क्वायर इंच,

मूल्य की इकाई : स्क्वायर इंच/स्क्वायर इंच

न्यूनतम आदेश मात्रा : 250

ज़ाइलन कोटिंग सर्विस

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : स्क्वायर इंच/स्क्वायर इंच

मूल्य की इकाई : स्क्वायर इंच/स्क्वायर इंच

न्यूनतम आदेश मात्रा : 1

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें