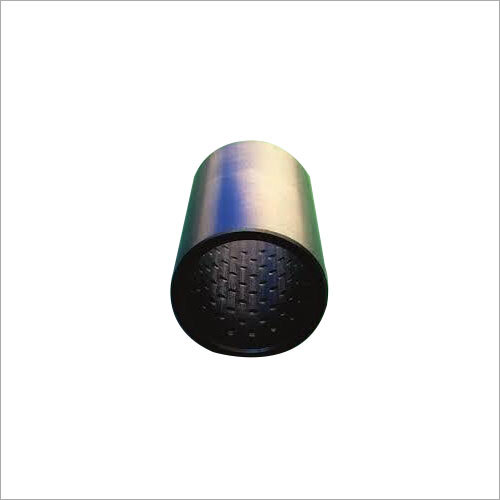

XYLAN PTFE Dry Lubricant Coating Service

Price 3 INR/ Square Inch

MOQ : 1000 Square Inches

XYLAN PTFE Dry Lubricant Coating Service Specification

- Adhesion Strength

- Strong adhesion to metal substrates

- Features

- Non-Stick, Low Friction, Corrosion Resistant, Chemical Resistant

- Maximum Working Temperature

- 260°C

- Uses/Industries

- Automotive, Oil & Gas, Engineering, Fasteners, Industrial Machinery

- Service Name

- XYLAN PTFE Dry Lubricant Coating Service

- Color

- Blue

- Shelf Life

- Up to 24 months under proper storage

- Hardness

- Excellent durability and hardness

- Safety Compliance

- Meets international industrial coating safety standards

- Application Method

- Spray and Bake

- Coating Thickness

- 20-40 microns

- Surface Finish

- Smooth and uniform

- Environmental Resistance

- Resistant to solvents and environmental exposure

- Coating Material

- XYLAN PTFE

- Curing Type

- Thermal Oven Cured

- Service Location

- On-site/Off-site available

XYLAN PTFE Dry Lubricant Coating Service Trade Information

- Minimum Order Quantity

- 1000 Square Inches

- Supply Ability

- 100 Square Inches Per Week

- Delivery Time

- 7 Days

About XYLAN PTFE Dry Lubricant Coating Service

XYLAN 1010

Product Specifications :-

Customer must test for application suitability.

- XYLAN 1010 is an organic solvent based, resin - bonded , thermosetting , PTFE based dry lubricant / easy clean coating. It offers optimum low friction to wear resistance ratio and is used to reduce friction, prevent scoring and galling or to provide secondary lubrication

- This is our most widely used dry lubrication product, having excellent low friction and wear resistant properties. It is and ideal coating for use in bearing surfaces, either dry or in combination with mineral oil lubricants. It is an excellent metal treatment for reduction in friction, fretting, galling and other friction and interference related problems. It has excellent resistance to commonly used machine fluids, eg: - mineral oils and greases, petroleum, jet fuel, skydrol and other hydraulic fluids and can therefore be used in most common light and medium engineering applications.

Product Specifications :-

- Relative Density :- 1.05 g / cm

- Operating Temperature range :- -195oC to +285oC.

- Dry Film Thickness :- 25 to 30 microns

- Can Be Applied On Most Common Metals

Customer must test for application suitability.

Superior Protection for Metal Surfaces

XYLAN PTFE coating creates a non-stick, low-friction barrier with strong adhesion and resistance to corrosion and chemicals. This service ensures that critical components remain reliable and protected in harsh operational environments, making it ideal for industrial applications where longevity and performance are paramount.

Efficient Application and Curing Process

Our coating service utilizes a precision spray and thermal oven curing method, resulting in a smooth, uniform, and durable finish. The process maximizes adhesion and hardness, while also delivering consistent quality for complex shapes and assemblies, minimizing downtime and ensuring rapid turnaround.

Comprehensive Safety and Compliance

Prioritizing safety, XYLAN PTFE Dry Lubricant Coating complies with international industrial standards for health and environmental safety. The service provider operates across India, offering flexibility with on-site and off-site servicing options, tailored to your project requirements and operational needs.

FAQs of XYLAN PTFE Dry Lubricant Coating Service:

Q: How is XYLAN PTFE Dry Lubricant Coating applied to metal surfaces?

A: The coating is applied using a spray method, followed by thermal oven curing. This ensures excellent adhesion, a smooth and uniform finish, and achieves consistent thickness between 20 and 40 microns.Q: What are the main benefits of choosing this dry lubricant coating service?

A: XYLAN PTFE coating offers superior non-stick properties, low friction, high chemical and corrosion resistance, robust hardness, and long-lasting protection. It effectively extends the service life of components in demanding environments.Q: When is XYLAN PTFE coating recommended for industrial use?

A: This coating is ideal for applications that require strong environmental resistance and durability, such as automotive, oil & gas, engineering, fasteners, and industrial machinery operations, especially when exposure to chemicals and high temperatures up to 260C is involved.Q: Where is the XYLAN PTFE Dry Lubricant Coating Service available?

A: The service is available both on-site and off-site across India, allowing flexibility for different customer requirements and operational setups.Q: What is the process for scheduling and receiving the coating service?

A: Customers can contact the provider for consultation, followed by substrate preparation, spray application, oven curing, and inspection. Both on-location and remote coating services are offered depending on project needs.Q: How long does the coated product last under proper storage?

A: When stored under recommended conditions, the XYLAN PTFE coating retains its properties and effectiveness for up to 24 months, ensuring long-term reliability.Q: Does the service comply with safety and environmental standards?

A: Yes, the XYLAN PTFE Dry Lubricant Coating Service meets international industrial coating safety standards, ensuring a safe application process and environmentally responsible handling.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in XYLAN Coating Category

Thermowell PTFE Coating Service

Price 20 INR / Square Inch

Minimum Order Quantity : 1000 Square Inches

XYLAN PTFE Coating for Nut Bolts

Price 3 INR / Square Inch

Minimum Order Quantity : 1000 Square Inches

XYLAN PTFE Fastener Coating Service

Price 3 INR / Square Inch

Minimum Order Quantity : 1000 Square Inches

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free