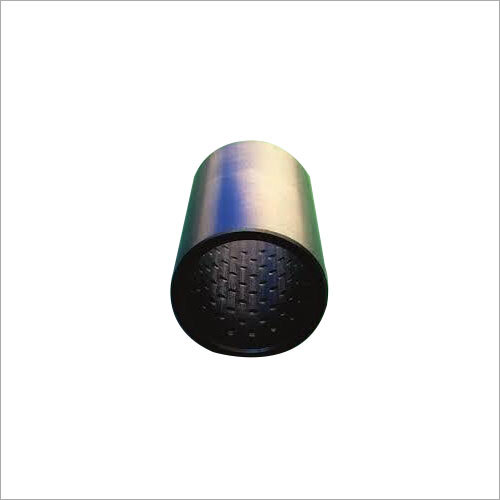

Xylan 1010 Coating Services

Price 3 INR/ Square Inch

MOQ : 250 Square Inches

Xylan 1010 Coating Services Specification

- Color

- Customizable (Blue, Green, Black, etc.)

- Usage

- Industrial, Automotive, Chemical processing, Food processing equipment

- Adhesion

- Excellent adhesion to substrates

- Environmental Compliance

- RoHS compliant

- Coating Thickness

- 15-25 microns

- Finish Type

- Matte or Glossy

- Coating Material

- Xylan 1010

- Curing Process

- Thermal curing required

- Product Code

- Xylan 1010

- Dry Film Thickness

- Typically 15-25 µm

- Surface Preparation

- Sandblasting or chemical cleaning recommended prior to coating

- Features

- Low friction, excellent wear and chemical resistance, non-stick properties

- Temperature Resistance

- Up to 285°C

- Maximum Operating Pressure

- Up to 70 Bar

- Application Method

- Spray or Dip

- Substrates

- Metal, Stainless Steel, Aluminum

- Corrosion Resistance

- High protection against rust and corrosion

- Hardness

- 60-85 Shore D

- Service Type

- Xylan 1010 Coating Services

About Xylan 1010 Coating Services

Xylan is a type of coating that is also done on daily-use products, like non-stick cookware. This industrial coating can also be done on several industrial parts and components. Companies which do not have the provision to carry out the coating can contact us for our Xylan 1010 coating services. This non-stick coating can improve the characteristics of products, such as durability, reduced durability and improved wear and corrosion resistance. The industries in which this type of coating is very popular are oil, gas and automobile.

Superior Protection Against Corrosion

Xylan 1010 coatings offer high protection against rust and corrosion, making them ideal for challenging industrial environments. The advanced technology ensures a robust barrier on components, promoting longer service life and reducing maintenance frequency. These features are essential for sectors such as chemical processing, automotive manufacturing, and food equipment.

Excellent Adhesion and Versatile Application

Thanks to its excellent adhesion properties, Xylan 1010 securely bonds to a variety of substrates like metals, stainless steel, and aluminum. The coating process, which involves surface preparation and thermal curing, ensures a uniform finish. Available in both spray and dip methods, the service offers flexible solutions for complex or simple components.

Customizable Finishes for Diverse Needs

With options for matte or glossy, and colors ranging from blue, green, black, and more, Xylan 1010 coatings can be tailored to suit specific branding or operational requirements. This adaptability ensures compatibility with your design and function, while maintaining high performance and aesthetic appeal.

FAQ's of Xylan 1010 Coating Services:

Q: How is Xylan 1010 coating applied to metal substrates?

A: Xylan 1010 coating can be applied using either spray or dip methods onto metal, stainless steel, or aluminum substrates. Prior to application, surface preparation such as sandblasting or chemical cleaning is recommended to achieve optimal adhesion. A thermal curing process is then carried out to ensure proper film formation and performance.Q: What is the maximum operating pressure that Xylan 1010 coating can withstand?

A: Xylan 1010 coatings are designed to tolerate operating pressures up to 70 Bar, making them suitable for demanding industrial and automotive environments where components are exposed to high-pressure conditions.Q: When should Xylan 1010 coating services be considered for equipment or components?

A: Xylan 1010 coating services are recommended when you need enhanced corrosion resistance, low friction, non-stick properties, and durability for equipment or parts used in industrial, chemical, automotive, or food processing applications.Q: Where can Xylan 1010 coating services be availed in India?

A: Xylan 1010 coating services are offered by industrial service providers across India, specializing in surface treatments for various sectors such as manufacturing, automotive, and food processing industries.Q: What is the process involved for preparing surfaces prior to Xylan 1010 coating application?

A: Surfaces should undergo sandblasting or chemical cleaning to remove contaminants and create a roughened texture, facilitating excellent adhesion of the Xylan 1010 coating during application.Q: What are the main benefits of choosing Xylan 1010 coating for industrial components?

A: Benefits include high corrosion protection, excellent substrate adhesion, resistance to chemicals and wear, low friction, customizable finishes, and temperature resistance up to 285C. These features enhance longevity and performance of machinery and equipment.Q: Can the color and finish of Xylan 1010 coating be customized for my application?

A: Yes, Xylan 1010 coatings are available in a range of colors such as blue, green, and black, and can be finished in matte or glossy styles. This flexibility allows for alignment with specific branding, functional, or aesthetic requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in XYLAN Coating Category

Thermowell PTFE Coating Service

Price 20 INR / Square Inch

Minimum Order Quantity : 1000 Square Inches

XYLAN PTFE Dry Lubricant Coating Service

Price 3 INR / Square Inch

Minimum Order Quantity : 1000 Square Inches

Xylan Ptfe Coating For High Pressure Application

Price 4 INR / Square Inch

Minimum Order Quantity : 1000 Square Inches

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS